Home > News > The 2.4m double S production line exported to Pakistan has been successfully put into operation

News

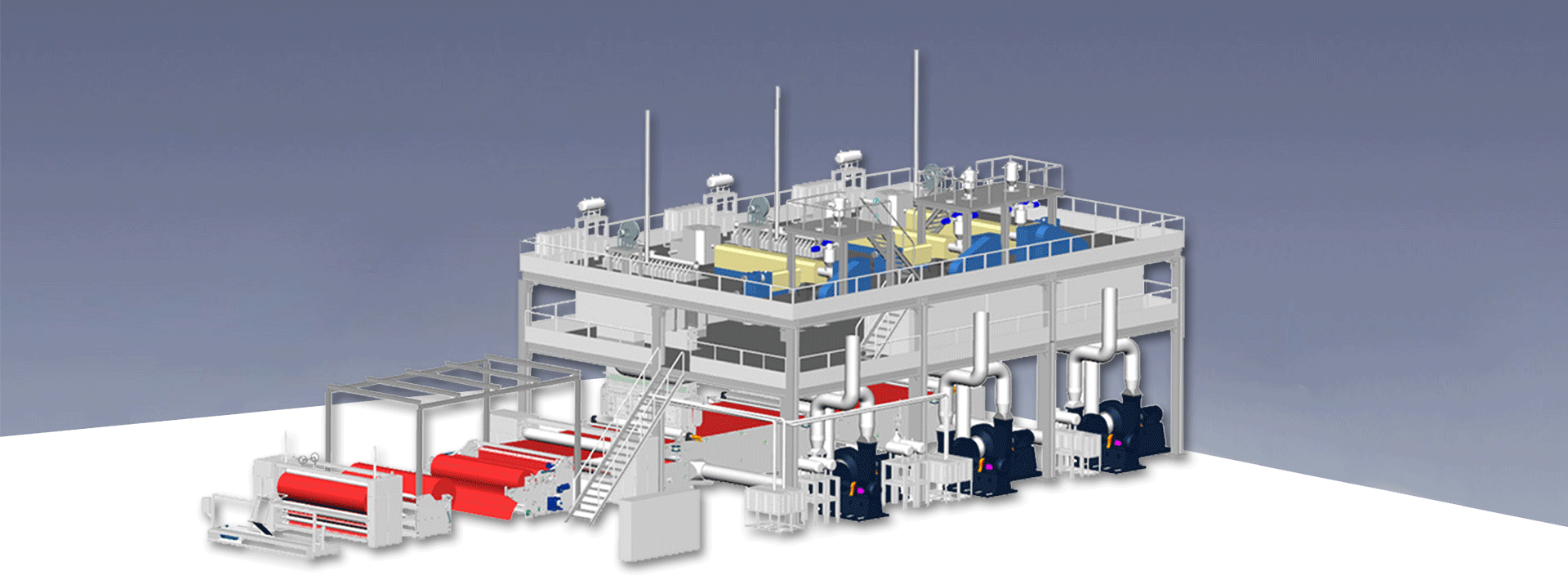

The 2.4m double S production line exported to Pakistan has been successfully put into operation

In June 2021, the double S Spunbonded non-woven fabric production line exported to Pakistan has been successfully installed, debugged and put into production,

The demand for non-woven fabrics in the current market is still very large. How to achieve rapid production of large quantities of non-woven fabrics requires the use of some automated mechanical equipment. Automatic mechanical equipment can provide higher output and higher quality for non-woven fabrics. It is very important to use professional Non-woven equipment. Now many non-woven fabric manufacturers need to use non-woven equipment. What are the performance characteristics of professional non-woven equipment? Now let's get to know about it. 1. Professional non-woven equipment has been optimized in structure, and it is more compact. The non-woven equipment can integrate all the tools needed for non-woven processing into one equipment to achieve unified coordination. Therefore, professional non-woven equipment is often small in size. 2. Smooth operation is an important prerequisite to ensure the production and quality of non-woven fabrics. The non-woven equipment that can maintain stable operation continuously can unify the quality of non-woven fabrics, achieve better product price effect, and promote the production of non-woven fabrics. 3. The non-woven fabric equipment uses the aluminum profile frame as the main body, which has a solid and durable structure, is not easy to rust, has a long service life, and is relatively convenient to install and maintain. Therefore, the experience of using the non-woven fabric equipment is quite good. 4. The automatic control mode of non-woven equipment can realize rapid and batch production of non-woven fabrics, so it can reduce labor costs and bring higher benefits to enterprises while increasing the production of non-woven fabrics. Non woven machinery and equipment are widely used in various social strata, economic fields and industries, especially in the construction industry, automobile repair industry, clothing industry, medical industry, aerospace industry and environmental protection industry. In addition, the use of non-woven fabrics in the health industry, especially in sanitary products, has been expanding, creating a new development in medical textiles, clothing textiles, vehicle textiles and other fields, forming a competitive advantage of non-woven fabrics with high added value and high economic benefits.

The production process of nonwoven equipment is gradually sophisticated. As far as the development situation of nonwoven equipment in China at that time is concerned, its production line is growing rapidly, and the production process is constantly sophisticated and improved in the process of production and development. At present, advanced production processes such as melt blown non-woven fabric production line, spunbonded non-woven fabric production line, needle punched non-woven fabric production line, spunlaced non-woven fabric production line, glue sprayed cotton production line and silk like cotton production line have been formed in China's non-woven fabric production process.

Non woven fabric is a kind of fabric that can be used in many occasions at present, and the production and improvement of non-woven equipment is also of great significance for this industry, because as a new type of fabric, non-woven fabric has a lot of room for development both in performance and in production mode. In the manufacturing and development of production equipment, we must pay attention to the problem of efficiency. At present, the production efficiency of non-woven fabrics is good, but it is still far from reaching the saturation value. There is still much to be done in terms of production speed and quality efficiency. Let's talk about the energy consumption of nonwoven equipment itself. Now, the production of nonwoven fabrics needs to consume a lot of water, oil, coal, electricity, etc., which not only causes a lot of material use, but also is a cost burden inferior to the production of nonwoven fabrics. To solve this problem will * * improve the application of nonwoven fabrics. In terms of non-woven fabric materials, the current equipment development route should pay attention to the use of some pollution-free and safe materials. In any case, environment-friendly and healthy non-woven fabrics must be more popular than chemical synthetic non-woven fabrics, and this development direction will not change.

The demand for non-woven fabrics in the current market is still very large. How to achieve rapid production of large quantities of non-woven fabrics requires the use of some automated mechanical equipment. Automatic mechanical equipment can provide higher output and higher quality for non-woven fabrics. It is very important to use professional Non-woven equipment. Now many non-woven fabric manufacturers need to use non-woven equipment. What are the performance characteristics of professional non-woven equipment? Now let's get to know about it. 1. Professional non-woven equipment has been optimized in structure, and it is more compact. The non-woven equipment can integrate all the tools needed for non-woven processing into one equipment to achieve unified coordination. Therefore, professional non-woven equipment is often small in size. 2. Smooth operation is an important prerequisite to ensure the production and quality of non-woven fabrics. The non-woven equipment that can maintain stable operation continuously can unify the quality of non-woven fabrics, achieve better product price effect, and promote the production of non-woven fabrics. 3. The non-woven fabric equipment uses the aluminum profile frame as the main body, which has a solid and durable structure, is not easy to rust, has a long service life, and is relatively convenient to install and maintain. Therefore, the experience of using the non-woven fabric equipment is quite good. 4. The automatic control mode of non-woven equipment can realize rapid and batch production of non-woven fabrics, so it can reduce labor costs and bring higher benefits to enterprises while increasing the production of non-woven fabrics. Non woven machinery and equipment are widely used in various social strata, economic fields and industries, especially in the construction industry, automobile repair industry, clothing industry, medical industry, aerospace industry and environmental protection industry. In addition, the use of non-woven fabrics in the health industry, especially in sanitary products, has been expanding, creating a new development in medical textiles, clothing textiles, vehicle textiles and other fields, forming a competitive advantage of non-woven fabrics with high added value and high economic benefits.

The production process of nonwoven equipment is gradually sophisticated. As far as the development situation of nonwoven equipment in China at that time is concerned, its production line is growing rapidly, and the production process is constantly sophisticated and improved in the process of production and development. At present, advanced production processes such as melt blown non-woven fabric production line, spunbonded non-woven fabric production line, needle punched non-woven fabric production line, spunlaced non-woven fabric production line, glue sprayed cotton production line and silk like cotton production line have been formed in China's non-woven fabric production process.

Non woven fabric is a kind of fabric that can be used in many occasions at present, and the production and improvement of non-woven equipment is also of great significance for this industry, because as a new type of fabric, non-woven fabric has a lot of room for development both in performance and in production mode. In the manufacturing and development of production equipment, we must pay attention to the problem of efficiency. At present, the production efficiency of non-woven fabrics is good, but it is still far from reaching the saturation value. There is still much to be done in terms of production speed and quality efficiency. Let's talk about the energy consumption of nonwoven equipment itself. Now, the production of nonwoven fabrics needs to consume a lot of water, oil, coal, electricity, etc., which not only causes a lot of material use, but also is a cost burden inferior to the production of nonwoven fabrics. To solve this problem will * * improve the application of nonwoven fabrics. In terms of non-woven fabric materials, the current equipment development route should pay attention to the use of some pollution-free and safe materials. In any case, environment-friendly and healthy non-woven fabrics must be more popular than chemical synthetic non-woven fabrics, and this development direction will not change.